Views: 0 Author: Site Editor Publish Time: 2025-08-06 Origin: Site

Did you know that one of the most versatile plastics is found in everyday products from food containers to industrial pipes? High-Density Polyethylene (HDPE) is a remarkable material that has been used for decades, dating back to its creation in the 1930s. It became commercially popular after World War II and has since revolutionized various industries.

In this post, we’ll explore what HDPE is, its history, and why it’s such a crucial material in modern manufacturing. You’ll learn about its incredible durability, versatility, and common uses, including HDPE Sheets and how they play a key role in everyday applications.

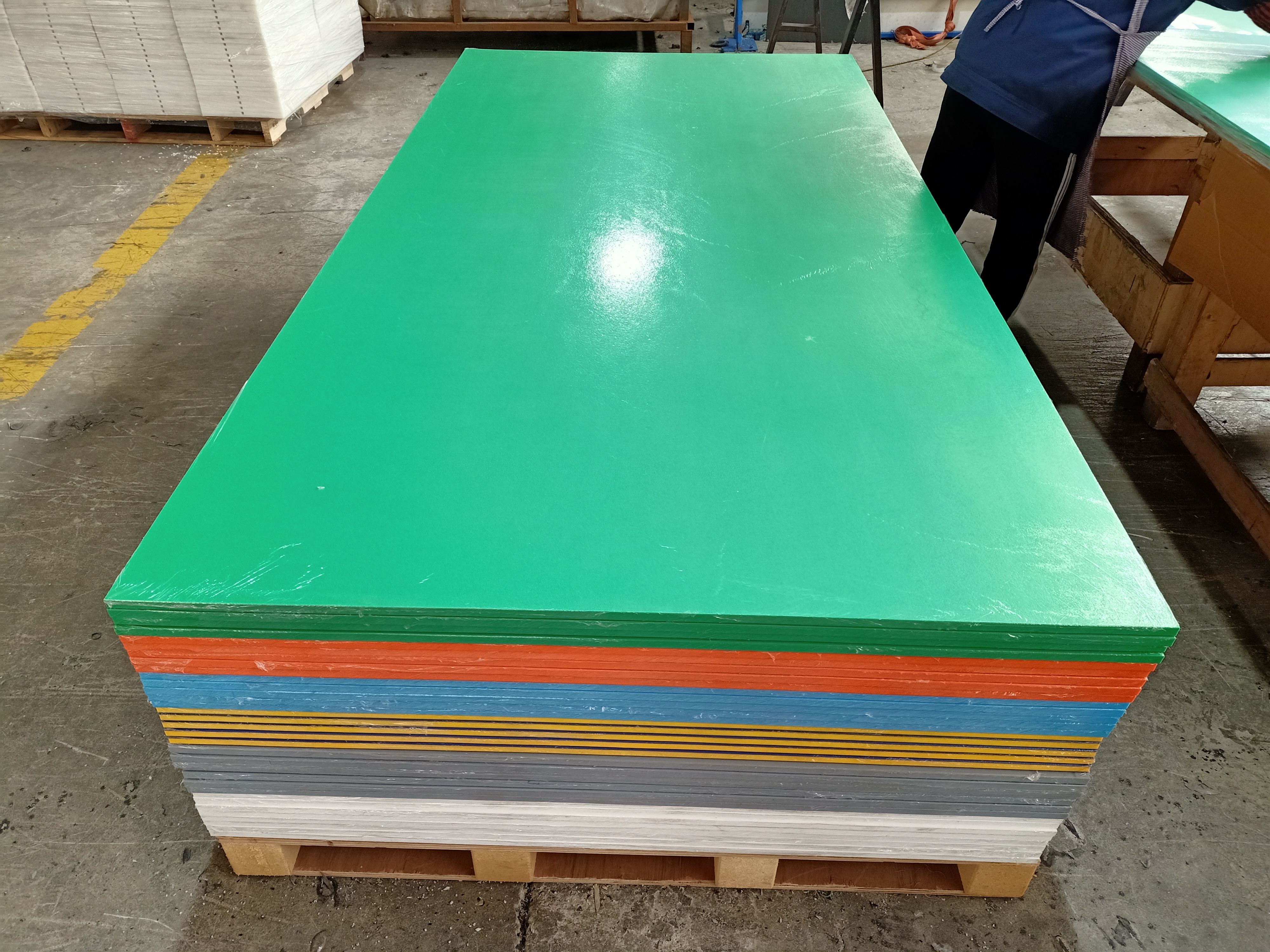

HDPE (High-Density Polyethylene) Sheet is a strong, versatile thermoplastic made from petroleum. Its molecular structure is characterized by long, linear chains, giving it exceptional strength and durability. These sheets are commonly available in various grades and thicknesses, allowing them to be used in a wide range of applications.

Common Grades and Thicknesses of HDPE Sheets:

Grades: HDPE Sheets come in different grades, including standard, food-grade, and UV-resistant options.

Thicknesses: Typically, HDPE Sheets range from 1/16” to 4” in thickness, making them adaptable to various needs in manufacturing and industrial settings.

HDPE Sheets are widely preferred due to their ability to withstand harsh environments while maintaining form and structure. Their ease of use in fabrication processes, like cutting, welding, and machining, makes them ideal for both industrial and consumer applications.

Cost-Effectiveness: HDPE Sheets are affordable, providing high performance at a lower cost compared to other materials.

UV Resistance: HDPE Sheets resist UV degradation, making them suitable for outdoor applications where sun exposure is common.

Durability & Strength: These sheets have a high strength-to-density ratio, meaning they are tough yet lightweight, ideal for demanding applications.

Chemical Resistance: HDPE Sheets are highly resistant to many chemicals, ensuring they maintain integrity even in harsh chemical environments.

Non-Leaching: The material does not leach chemicals, making it safe for food and water storage.

Easy to Fabricate: HDPE Sheets are easy to cut, weld, and mold, making them a versatile option for manufacturing.

Incorporating HDPE Sheets into your products or projects offers long-lasting, reliable solutions.

HDPE Sheets are widely used in manufacturing due to their strength and versatility. In the production of containers and storage units, HDPE Sheets are commonly used to make products like bottles, tanks, and drums. Their chemical resistance and durability ensure that these products maintain their integrity, even when exposed to harsh conditions.

Food and Beverage Industry: In the food industry, HDPE Sheets are used to produce food-safe containers, cutting boards, and trays. Thanks to its non-leaching properties, HDPE ensures that food products remain safe and uncontaminated.

Industrial and Agricultural Applications: HDPE Sheets are also crucial in industries like agriculture and construction. They are used in making pipes, liners, and coatings, especially in applications that require moisture resistance and chemical durability. HDPE Sheets provide a reliable solution for industrial storage and environmental protection.

HDPE Sheets are gaining popularity in construction due to their strength and weather resistance. They are used in flooring, wall panels, and insulation. Their ability to withstand temperature fluctuations and resist moisture makes them an excellent choice for building materials.

In heavy-duty construction, HDPE Sheets are used as protective covers, barriers, and geotechnical products. These applications rely on HDPE’s durability to protect structures from external elements.

Everyday consumer products also benefit from the properties of HDPE Sheets. Toys, playground equipment, recycling bins, and storage containers are commonly made from HDPE.

Advantages for Consumer Safety and Hygiene: HDPE Sheets are non-toxic and resistant to bacteria, which makes them a safe choice for consumer goods. They are easy to clean, which is why they are preferred in products designed for daily use.

HDPE Sheets are created through a process called polymerization. The process begins with petroleum, which is heated to break down hydrocarbons into smaller molecules. These molecules then combine into long chains, forming HDPE (High-Density Polyethylene), a thermoplastic polymer.

Overview of HDPE Sheet Production:

Extrusion: The polymerized HDPE is melted and forced through a mold to form sheets of various thicknesses. This method ensures consistency in shape and size.

Forming: Once extruded, the HDPE Sheets are cooled and hardened, maintaining their shape. They are then cut to the required dimensions for further use.

Cutting: After forming, HDPE Sheets can be trimmed to size using cutting machines to ensure precision.

HDPE Sheets can be customized to suit specific applications by various fabrication methods. These processes allow manufacturers to create products tailored to industry needs.

Cutting, Welding, and Joining HDPE Sheets:

Cutting: HDPE Sheets can be easily cut using various tools, such as saws, routers, and CNC machines, allowing for flexibility in design.

Welding and Joining: HDPE can be welded using heat or by using adhesives designed for plastic, making it easy to join sheets together for larger structures or products.

Popular Fabrication Methods for Bespoke HDPE Products:

CNC Machining: This technique allows for precise shaping and cutting of HDPE Sheets into custom designs. CNC machining is ideal for complex shapes and ensures high accuracy.

These fabrication techniques make HDPE Sheets an adaptable choice for a wide range of industries.

High Strength-to-Weight Ratio: HDPE Sheets are lightweight yet incredibly strong, making them ideal for a wide range of applications without adding unnecessary bulk.

Excellent Weathering and Corrosion Resistance: HDPE is highly resistant to the elements, such as UV radiation, moisture, and various chemicals. This makes it suitable for outdoor and industrial environments.

Eco-friendly and Recyclable: HDPE Sheets are 100% recyclable, reducing environmental impact. This feature aligns with sustainable practices, making it a preferred material for eco-conscious industries.

High Impact Resistance and Easy Maintenance: HDPE Sheets can withstand significant impacts without cracking or breaking, while also being easy to clean and maintain, ensuring long-term use.

Poor Bonding Properties: HDPE Sheets are difficult to glue or paint due to their smooth surface and low surface energy. Special adhesives or welding techniques are required for bonding.

Sensitive to Stress Cracking: Under certain conditions, HDPE Sheets can experience stress cracking, especially in harsh environments or when exposed to concentrated mechanical pressure.

Not Biodegradable: Although recyclable, HDPE Sheets do not biodegrade naturally, meaning they can contribute to environmental waste if not properly recycled.

Despite these limitations, HDPE Sheets remain a popular material due to their many advantages in various industries.

HDPE Sheets are used in many everyday household products, making them an essential material in daily life. For instance, milk jugs, shampoo bottles, and laundry detergent containers are typically made from HDPE due to its durability and non-leaching properties. These products benefit from the material's strength and resistance to chemicals, ensuring long-lasting use.

Other common household items include recycling bins, grocery bags, and plastic packaging. HDPE’s resistance to wear and tear makes it an ideal choice for products that require frequent handling and cleaning.

In industrial applications, HDPE Sheets are highly valued for their versatility and toughness. Chemical containers and corrosion-resistant tanks made from HDPE are ideal for storing hazardous materials. The material's ability to withstand harsh chemicals and extreme temperatures makes it perfect for these applications.

HDPE Sheets are also used in pipe systems for water, sewage, and gas. Their resistance to abrasion, UV degradation, and chemical corrosion makes them an excellent choice for long-lasting, reliable piping solutions.

In the marine industry, HDPE Sheets are used for boat hulls, water tanks, and dock components due to their water resistance and durability.

HDPE Sheets are widely used in the food industry due to their food-safe properties. Cutting boards and storage containers made from HDPE are non-toxic, easy to clean, and resistant to bacterial growth, ensuring safe food handling.

In medical applications, HDPE Sheets are used to make medical-grade devices and storage containers. The material’s ability to be sterilized and its high strength make it ideal for medical environments where hygiene and safety are crucial.

One of the standout features of HDPE Sheets is their recyclability. After use, HDPE can be melted down and reformed into new products, reducing the need for new plastic. HDPE Sheets are typically marked with a #2 recycling symbol, which makes it easy to identify them for recycling.

Benefits of Recycling HDPE:

Reduced Waste: Recycling HDPE helps keep plastic waste out of landfills, reducing environmental impact.

Energy Conservation: Recycled HDPE requires less energy to process than new plastic, reducing the carbon footprint.

Resource Conservation: By reusing HDPE, we can preserve natural resources, decreasing the need for petroleum-based products.

Recycling HDPE Sheets not only minimizes waste but also supports a circular economy, helping to reduce the overall environmental burden of plastic products.

HDPE Sheets are considered more environmentally friendly than many other plastics. Unlike some materials, HDPE Sheets are durable and require less maintenance, which helps extend the product's life cycle.

How HDPE Compares to Other Plastics:

Lower Environmental Footprint: HDPE is easier to recycle and has a lower environmental footprint than plastics like PVC or polystyrene. Its long lifespan also reduces the frequency of replacement, helping conserve resources.

Energy Efficiency: The production of HDPE Sheets consumes less energy compared to some other plastics, making it a more sustainable choice.

Ways to Minimize Waste and Promote Sustainable HDPE Use:

Encourage Recycling: Proper disposal and recycling of HDPE Sheets can significantly reduce waste.

Reduce Single-Use Products: By opting for durable and reusable HDPE Sheets in products, we can minimize single-use plastic consumption.

Promote Upcycling: In some cases, old HDPE Sheets can be creatively repurposed into new items, further reducing waste.

Incorporating HDPE Sheets into sustainable practices ensures a positive impact on the environment and supports a more circular economy.

HDPE Sheets offer unmatched versatility, durability, and cost-effectiveness, making them the ideal choice for various industries. From household items to industrial applications, HDPE Sheets provide long-lasting solutions. Their recyclability and strength make them an eco-friendly and reliable option.

For businesses looking for high-quality HDPE Sheets, ABSON products stand out, offering excellent performance and value for your investment.

A: Yes, HDPE is FDA-approved for food storage and safe for direct contact with consumables.

A: HDPE Sheets are recyclable and are identified by the #2 plastic recycling symbol, making them eco-friendly.

A: HDPE Sheets are highly durable and perform well in extreme temperatures, ranging from -148°F to 176°F (-100°C to 80°C).

A: HDPE Sheets are sensitive to stress cracking under specific conditions and are not resistant to oxidizing acids.