Views: 0 Author: Site Editor Publish Time: 2025-08-05 Origin: Site

Durability and resistance to moisture or chemicals

Waterproof qualities for outdoor or marine settings

Maintenance requirements and long-term cost-effectiveness

Environmental impact and recyclability

You should always match the HDPE Sheet or plywood to the demands of your specific environment and application.

HDPE sheets offer superior waterproofing and resist moisture, chemicals, and UV rays better than plywood.

Plywood provides strong rigidity and load-bearing capacity but can warp, rot, or swell when exposed to moisture.

HDPE is flexible and impact-resistant, making it ideal for curved surfaces and harsh outdoor environments.

Marine-grade HDPE lasts over 50 years with minimal maintenance, while plywood typically lasts 10 to 30 years and needs regular upkeep.

HDPE sheets are slip-resistant and safer for wet or marine settings, reducing risks of slips and falls.

Choosing HDPE reduces long-term costs due to lower maintenance and fewer replacements compared to plywood.

HDPE supports sustainability through recyclability and a lower environmental impact than plywood.

Select HDPE for outdoor, marine, or high-traffic projects; choose plywood for indoor or structural uses needing traditional wood aesthetics.

When you compare HDPE sheet and plywood, you see that both materials offer unique strengths for different applications. Recent studies show that HDPE-bonded plywood panels can match the mechanical properties of traditional plywood bonded with urea-formaldehyde (UF) or phenol-formaldehyde (PF) adhesives. This means you get similar strength and durability, but with added benefits from HDPE’s properties.

HDPE bonding reduces thickness swelling and water absorption. The plastic fills wood micropores and covers surfaces, making the panel more resistant to moisture.

You use less adhesive and lower pressing pressure with HDPE, which helps the environment by reducing formaldehyde emissions.

When you press HDPE at the right temperature and time, it flows into wood vessels and cracks, creating a strong mechanical bond.

HDPE-bonded plywood meets European standards for dry condition strength, showing its reliability in many settings.

HDPE film also increases flexibility, making it easier to use in curved or bent constructions.

A comparative analysis of HDPE sheet and plywood highlights that HDPE panels, especially those using virgin HDPE, show higher bending strength and lower water absorption than panels with recycled HDPE. The addition of coupling agents like PE-g-MA further improves the bond between wood and HDPE, leading to better mechanical performance and moisture resistance.

You notice several important differences when you look at HDPE sheet and plywood side by side.

Moisture Resistance: HDPE sheet stands out for its waterproof qualities. Plywood, even when treated, can absorb water and swell over time. HDPE-bonded plywood panels show much lower water uptake, making them ideal for wet or humid environments.

Strength and Flexibility: HDPE sheet offers excellent impact resistance and flexibility. Plywood provides rigidity and strong load-bearing capacity, but HDPE panels can bend without breaking, which is useful for curved surfaces.

Environmental Impact: HDPE sheets and HDPE-bonded plywood avoid formaldehyde emissions, making them safer for indoor use. Traditional plywood often uses adhesives that release formaldehyde, which can affect air quality.

Durability: HDPE sheet resists chemicals, UV rays, and weathering. Plywood may degrade or rot if exposed to harsh outdoor conditions for long periods.

Processing and Customization: You can customize HDPE sheets in thickness, color, and texture, such as the orange peel surface from ABOSN. Plywood offers fewer options for surface finish and color.

By understanding these key differences, you can choose the right material for your project, whether you need the flexibility and moisture resistance of HDPE or the structural rigidity of plywood.

When you choose an HDPE sheet for your project, you gain a material that excels in impact resistance. High-density polyethylene absorbs shocks and resists cracking, even under heavy loads or sudden impacts. This makes HDPE ground protection mats a top choice for construction sites, playgrounds, and events where you need reliable ground protection. The ABOSN HDPE Orange Peel Textured Surface Plastic Waterproof HDPE Slip Sheet delivers high performance in demanding environments. You can use these mats repeatedly without worrying about dents or fractures, which ensures long-term protection for both equipment and surfaces.

HDPE ground protection mats stand out for their flexibility. You can bend or shape them to fit uneven terrain or curved surfaces, which is not possible with rigid materials. This flexibility allows you to create custom ground protection solutions for a wide range of applications. Whether you need to cover soft soil, grass, or sand, HDPE sheet adapts to the environment and maintains its protective qualities. The non-porous nature of high-density polyethylene also means you do not have to worry about water absorption, swelling, or loss of performance over time. This flexibility, combined with chemical and UV resistance, makes HDPE ground protection mats ideal for harsh outdoor conditions.

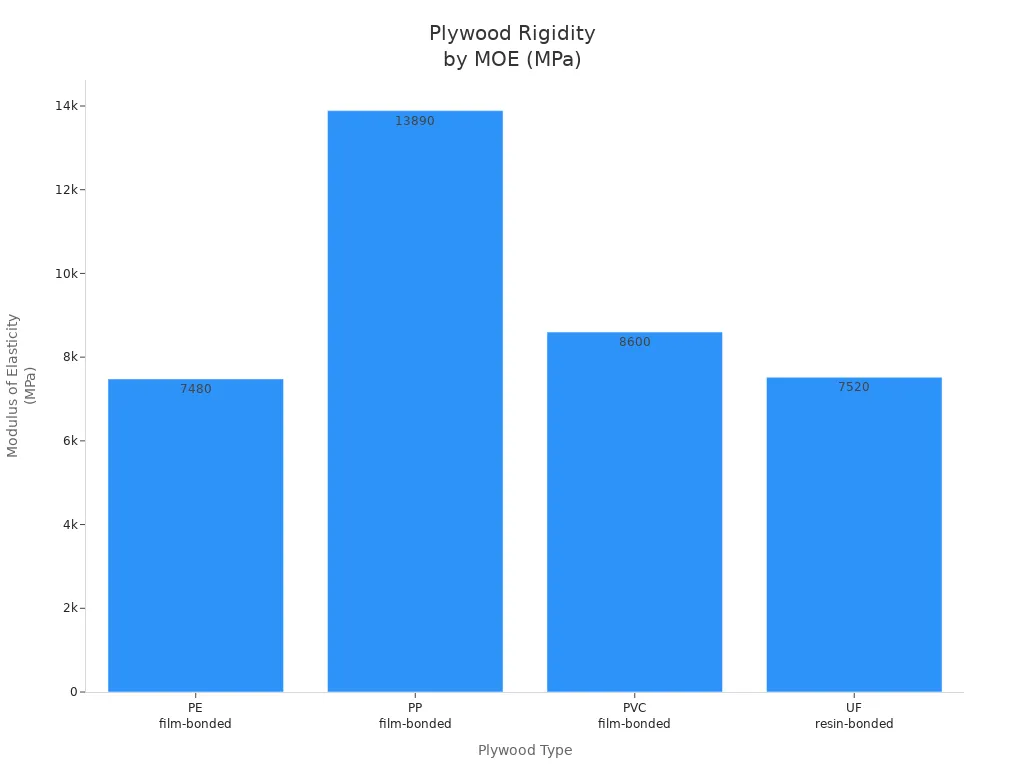

Plywood offers impressive rigidity and load-bearing capacity, especially when you use hardwood varieties like birch or black alder. You can rely on plywood for structural applications where strength and stiffness are critical. Studies show that reinforcing plywood with carbon fiber fabrics can boost its bending strength by up to 30%. This makes plywood a strong candidate for semi-structural and structural uses, such as flooring, wall panels, and temporary roadways. The following table compares the modulus of rupture and elasticity for different plywood types and HDPE sheets:

Material / Adhesive Type | Modulus of Rupture (MOR, MPa) | Modulus of Elasticity (MOE, MPa) | Bonding Strength (MPa) | Notes |

|---|---|---|---|---|

PE film-bonded plywood | 82.8 | 7480 | 1.5 (Type II) | High rigidity, suitable for indoor structural use |

PP film-bonded plywood | 109.3 | 13,890 | 1.9 (Type II), 1.4 (Type I) | Higher stiffness and strength than PE film plywood |

PVC film-bonded plywood | 65.1 | 8600 | 1.1 (Type II), 0.5 (Type I) | Moderate mechanical properties |

UF resin-bonded plywood | 75.7–94.5 | 7520–13,019 | 1.3–1.4 (Type II) | Thermosetting resin reference |

HDPE sheets | Lower stiffness and tensile strength compared to plywood | N/A | N/A | Less rigid, limiting structural use; better for chemical resistance and flexibility |

You see that plywood’s rigidity makes it a reliable option for projects that demand high load-bearing strength and minimal flex.

You often face challenges with plywood in wet or humid environments. Plywood can absorb moisture, which leads to swelling, warping, and even rot over time. Even marine-grade plywood, which uses waterproof glue, still requires regular maintenance to prevent damage. In contrast, HDPE ground protection mats provide superior protection against these issues. HDPE is a non-porous plastic that does not absorb water, so it will not swell, delaminate, or rot. You do not need to apply treatments, coatings, or sealants to maintain its durability. HDPE ground protection mats resist mold and mildew, making them a better choice for repeated use in wet or humid conditions. You can trust HDPE sheet to maintain its shape and function, even after exposure to rain, mud, or chemicals.

Tip: For projects in coastal, rainy, or high-traffic outdoor areas, HDPE ground protection mats offer unmatched protection and durability, reducing maintenance and replacement costs over time.

When you select marine-grade high-density polyethylene for outdoor or marine projects, you gain a material engineered for extreme environments. ABOSN’s HDPE Orange Peel Textured Surface Plastic Waterproof HDPE Slip Sheet features advanced UV stabilization. This means you get reliable protection against sun damage, fading, and brittleness. Unlike wood, which needs chemical treatments and regular maintenance to resist UV rays, hdpe marine boards maintain their color and structural integrity for years.

Marine-grade high-density polyethylene resists moisture and does not warp or crack like wood.

HDPE offers greater heat and UV resistance, so you spend less time and money on upkeep.

Traditional wood requires ongoing treatments to prevent UV damage and rot.

HDPE marine boards deliver better long-term durability and lower maintenance costs.

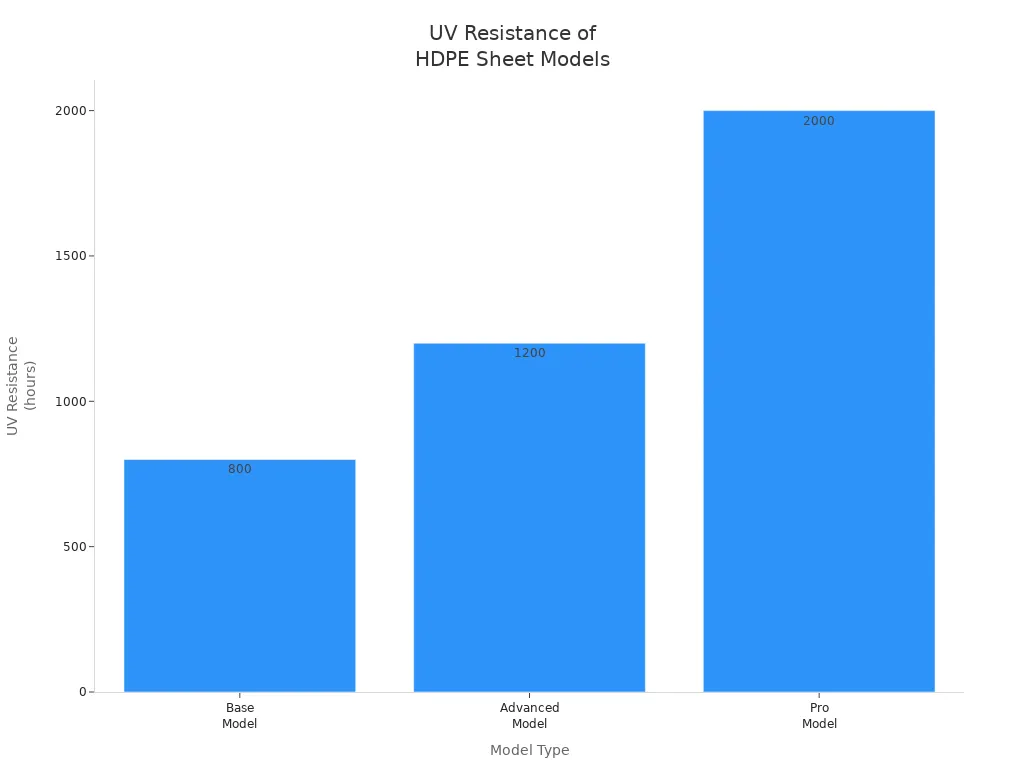

You can see the difference in UV resistance between various marine-grade high-density polyethylene models:

Model Type | UV Resistance (ASTM G154) | Key Benefit |

|---|---|---|

Base Model | 800 hours | UV-stabilized to withstand sun exposure |

Advanced Model | 1,200 hours (+50%) | Improved UV resistance over base model |

Pro Model | 2,000 hours (+150%) | Exceeds industry benchmarks by 150%, ideal for long-term outdoor use |

Marine-grade high-density polyethylene sheets outperform wood in marine decking by providing natural waterproof protection and eliminating the need for chemical treatments. You get a wood-like look with slip-resistant surfaces, but without the risk of fading, warping, or degradation.

You need materials that stand up to harsh weather, saltwater, and temperature swings. Marine-grade high-density polyethylene gives you complete waterproof protection. HDPE marine boards do not absorb water, so they never swell, rot, or delaminate. You can submerge them without damage, making them ideal for docks, piers, and marine decking.

Feature | Marine-grade HDPE Sheet | Marine Plywood |

|---|---|---|

Waterproof | Completely waterproof | Water-resistant, not waterproof |

Weather Resistance | Resistant to UV, chemicals, saltwater | Prone to rot, delamination, warping |

Maintenance | Virtually maintenance-free (wipe clean) | Requires sealing, painting, regular upkeep |

Durability | Maintains integrity 10+ years in harsh conditions | Degrades over time in marine environments |

Submersion | Can be submerged without damage | Not suitable for prolonged submersion |

HDPE marine boards resist corrosion and deterioration in saltwater. You do not have to worry about pests or mold. You get long-lasting protection and high performance, even in the toughest outdoor settings.

ABOSN’s HDPE Orange Peel Textured Surface Plastic Waterproof HDPE Slip Sheet gives you a unique surface that boosts safety. The orange peel texture increases grip, reducing the risk of slips and falls. This feature is especially important for marine decking, playgrounds, and wet environments where safety is a top priority.

HDPE marine boards provide a slip-resistant surface, even when wet.

The textured finish maintains its grip over time, unlike wood, which can become slick or splintered.

You can choose from different surface options to match your project’s safety and performance needs.

You want reliable protection in wet and humid environments. HDPE marine boards deliver complete waterproof protection and resist saltwater corrosion. They do not swell, rot, or support mold and mildew growth. This means you avoid common safety hazards found with wood, such as warping, cracking, and surface decay.

HDPE marine boards last 50+ years, resisting cracking, splintering, and pest damage.

Wood decking typically lasts 10-30 years, even with regular maintenance.

HDPE requires only simple cleaning, while wood needs sealing, staining, and repairs.

Note: A marina that switched from wood to hdpe marine boards reported zero fading, cracking, or corrosion after seven years, with no maintenance costs beyond cleaning.

When you compare the pros and cons of marine-grade high-density polyethylene vs. wood, you see clear advantages in safety, waterproof protection, and long-term performance. HDPE marine boards give you peace of mind, lower maintenance, and high performance in every application.

When you choose traditional wood marine decking, you rely on the strength of marine plywood. Manufacturers create marine plywood by cross-laminating wood layers, often using Douglas fir or western larch, and bonding them with moisture-resistant adhesives. This process gives marine plywood a reliable structure for many marine decking applications. You can expect good load-bearing capacity, but you must remember that marine plywood can bend under heavy loads if you do not provide enough support.

Here is a comparison of structural properties:

Property/Aspect | Traditional Wood Marine Decking (Marine-Grade Plywood) | Marine-Grade HDPE Sheet |

|---|---|---|

Material Composition | Cross-laminated wood layers with moisture-resistant adhesives | Thermoplastic polymer with high strength-to-density ratio |

Structural Strength | Reliable but prone to bending under load; needs extra support | Holds weight without bending or warping |

Moisture Resistance | Moisture-resistant but not fully waterproof; can rot or mold | Naturally moisture resistant; withstands submersion |

You see that marine plywood provides a solid base for decking, but it does not match the high modulus of elasticity found in marine-grade HDPE sheets. For projects where you need a rigid surface, marine plywood works well, but you must plan for additional support in high-traffic or heavy-load areas.

You should prepare for regular maintenance when you install marine plywood for marine decking. Marine plywood resists water better than standard plywood, but it is not completely waterproof. You need to seal and paint the surface to prevent water damage, rot, and swelling. Inspections are necessary to catch early signs of delamination or mold.

Consider this maintenance comparison:

Feature | Wood Marine Decking (Marine Plywood) | HDPE Sheet (Marine HDPE Board) |

|---|---|---|

Waterproof | Water-resistant but not fully waterproof; requires sealing | 100% waterproof; does not absorb moisture |

Maintenance | High: regular sealing, painting, inspection | Very low: cleaning with soap and water only |

Durability | Prone to rot, mold, warping, swelling, UV damage | Resistant to rot, cracking, splitting, UV, saltwater, chemicals |

Cleaning | Can stain or degrade; requires upkeep | Easy to clean; minimal upkeep |

You will spend time and resources on sealing, painting, and replacing damaged boards. Marine plywood can splinter or crack, especially in harsh marine environments. If you want a low-maintenance solution, you may find marine-grade HDPE sheets more appealing.

Tip: Regular maintenance extends the life of marine plywood, but you must stay vigilant to prevent costly repairs.

Marine plywood faces many challenges in outdoor and marine settings. Water, salt, and UV rays can break down the adhesives and wood fibers over time. Even with treatments, marine plywood absorbs some moisture, which leads to warping, rot, and mold. Saltwater exposure speeds up this process, making frequent inspections and repairs necessary.

Here is a summary of environmental factors:

Factor | Wood Marine Decking | HDPE Sheet |

|---|---|---|

Water Resistance | Absorbs moisture, prone to rot, mold, warping | Completely waterproof, impervious to saltwater |

UV Exposure | Fades and weakens fibers, needs sealing | UV-stabilized, resists fading and degradation |

Maintenance | Frequent sealing, staining, sanding, replacement | Minimal maintenance, occasional cleaning only |

Lifespan | 10-30 years with good maintenance | 50+ years with maintained integrity |

You can expect marine plywood to last 10 to 30 years, depending on the quality and how well you maintain it. In contrast, marine-grade HDPE sheets can last over 50 years with minimal care. For example, a marina in Florida replaced its wooden decking with HDPE sheets and saw no fading, cracking, or corrosion after seven years, while the old marine plywood deck needed yearly repairs.

Note: If you want a classic look and do not mind regular upkeep, traditional wood marine decking remains a popular choice. However, you should weigh the long-term maintenance and environmental exposure before making your decision.

You want materials that deliver reliable protection in every environment. HDPE sheets provide outstanding protection against water, chemicals, and UV rays. When you use HDPE for ground protection, you get a surface that does not absorb water. This means you avoid swelling, mold, and fungus growth. HDPE resists acids, bases, and solvents, so you can trust it for chemical protection in industrial and marine settings. The UV stabilization in HDPE ensures that sunlight will not cause fading or brittleness, even after years of exposure. Plywood cannot match this level of protection. Over time, plywood absorbs moisture and suffers from rot, warping, and delamination. You see HDPE used in potable water piping because of its chemical resistance and non-leaching properties. For ground protection mats, this translates to long-term performance and safety, even in harsh outdoor conditions.

HDPE sheets offer protection from aggressive chemicals and saltwater.

You get UV protection that keeps your ground protection mats looking new.

HDPE does not rot, splinter, or bulge, so you maintain protection year after year.

Tip: For projects that demand ground protection in wet, sunny, or chemically harsh environments, HDPE delivers unmatched protection and durability.

You save time and money on maintenance when you choose HDPE for ground protection. HDPE sheets require only simple cleaning with soap and water. You do not need to seal, paint, or treat the surface. Plywood, on the other hand, needs regular sealing, painting, and inspection to maintain protection. If you skip maintenance, plywood quickly loses its protective qualities. HDPE ground protection mats resist staining and do not support mold or mildew. You can deploy and reuse them with minimal effort. This ease of upkeep makes HDPE the preferred choice for ground protection in playgrounds, construction sites, and marine environments.

Minimal maintenance keeps your ground protection effective.

No need for special coatings or treatments.

HDPE ground protection mats stay ready for use, season after season.

Note: HDPE’s low-maintenance nature means you spend less time worrying about protection and more time focusing on your project.

You want ground protection that lasts. HDPE sheets provide a lifespan of over 50 years, even in demanding outdoor or marine environments. This long-term protection comes from the material’s resistance to water, chemicals, and UV rays. Plywood, even marine-grade, cannot offer the same longevity. Over time, plywood suffers from rot, mold, and structural breakdown, especially in moist or salty conditions. HDPE ground protection mats maintain their shape and strength, giving you greater longevity and consistent protection. You can rely on HDPE for ground protection that stands the test of time, reducing replacement costs and ensuring safety for decades.

Material | Typical Lifespan | Maintenance Needs | Resistance to Elements |

|---|---|---|---|

HDPE Sheet | 50+ years | Minimal | Water, UV, chemicals, salt |

Marine Plywood | 10–30 years | High | Water-resistant, not waterproof |

Choosing HDPE for ground protection means you invest in durability, protection, and longevity for every project.

When you start a project, you often look at the upfront cost of materials. HDPE sheets, such as ABOSN’s Orange Peel Textured Surface Plastic Waterproof HDPE Slip Sheet, usually cost more per square foot than marine plywood. This higher price reflects the advanced engineering, UV stabilization, and slip-resistant features built into each sheet. Plywood, on the other hand, offers a lower initial price and is widely available in standard sizes. If you have a tight budget or need a quick solution for a temporary project, plywood may seem attractive at first glance.

Material | Initial Cost | Key Features |

|---|---|---|

HDPE Sheet | Higher | Waterproof, UV-stabilized, slip-resistant, customizable |

Marine Plywood | Lower | Water-resistant, rigid, needs sealing |

Tip: Consider the total cost of ownership, not just the sticker price, when choosing materials for demanding environments.

You need to think beyond the first purchase. HDPE sheets deliver significant savings over time because they resist moisture, chemicals, UV rays, and physical damage. You do not have to worry about rot, warping, or splintering. Maintenance is simple—just clean with soap and water. In contrast, plywood absorbs moisture and degrades quickly in harsh conditions. You will find yourself replacing plywood every few months, especially in marine or outdoor settings. This frequent replacement increases your long-term costs and adds to waste disposal expenses. HDPE’s recyclability also helps reduce waste management costs. When you choose HDPE, you make a smart long-term investment that pays off with lower maintenance, fewer replacements, and less hassle.

You want the best value for your specific application. HDPE sheets shine in marine, outdoor, and high-traffic projects where durability and safety matter most. Here is why many professionals choose HDPE for these environments:

HDPE is fully waterproof and resists rot, mold, UV, and chemicals.

You avoid the ongoing costs of sealing, painting, and inspections required for plywood.

HDPE maintains its structural integrity for over 10 years, even in harsh conditions.

The material is lightweight, which lowers transportation costs.

You get a product that lasts over 50 years, making it a true long-term investment.

Plywood works well for indoor or temporary uses where exposure to moisture and heavy wear is limited. However, for marine docks, playgrounds, outdoor cabinetry, or high-traffic walkways, HDPE offers unmatched cost-effectiveness and peace of mind.

Note: Industry experts recommend HDPE as a modern, cost-efficient alternative to marine plywood, especially when you need a solution that stands up to moisture and outdoor exposure.

You want materials that support a healthier planet. HDPE sheets offer a sustainable option for many projects. The production process for HDPE uses an energy-efficient catalytic high-pressure polymerization method. This approach lowers the carbon footprint and reduces greenhouse gas emissions compared to other plastics. Because HDPE sheets last for decades, you replace them less often, which means you use fewer resources over time. When you choose HDPE instead of wood, you help reduce deforestation and conserve natural resources. HDPE boards also resist weather, chemicals, and corrosion, so you do not need to replace them as frequently as plywood. This durability supports sustainable building practices and helps you minimize your environmental impact.

Choosing HDPE for your project means you support long-term sustainability and reduce the need for frequent replacements.

You can recycle HDPE sheets with ease. The recycling process starts by shredding the material into small pieces. You can do this manually or with a shredder. After shredding, you melt the HDPE at controlled temperatures between 165°C and 215°C. The melted plastic forms pellets or granules, which you can then mold into new sheets or blocks. This process allows you to reuse HDPE multiple times without losing quality. HDPE’s recyclability makes it a top choice for eco-friendly projects. In contrast, plywood recycling is more difficult. Plywood often contains adhesives and coatings that complicate the recycling process. Most plywood ends up in landfills, where it can release harmful chemicals as it breaks down.

Material | Recyclability | Typical Process |

|---|---|---|

HDPE Sheet | High | Shredding, melting, pelletizing, remolding |

Plywood | Low | Limited; adhesives and coatings hinder recycling |

HDPE’s ability to be recycled into new products supports a circular economy and reduces waste.

You need to consider the full environmental impact of your material choices. HDPE boards are non-toxic and do not leach harmful chemicals. Their long lifespan means you generate less waste over time. When you use HDPE instead of plywood, you help protect forests and reduce the demand for timber. HDPE’s water resistance also supports green building and sustainable water management in agriculture and marine industries. On the other hand, traditional plywood production often relies on formaldehyde-based adhesives. These adhesives can emit toxic chemicals and lower indoor air quality. When you dispose of plywood, it may release these chemicals into the environment. By choosing HDPE, you avoid these issues and support a cleaner, safer ecosystem.

For projects where environmental impact matters, HDPE stands out as a responsible and sustainable option.

You can rely on hdpe sheet for a wide range of demanding environments. In marine and outdoor settings, hdpe ground protection mats deliver unmatched durability and protection. You see these mats used on construction sites, playgrounds, and marinas where moisture, chemicals, and UV rays threaten traditional materials. Hdpe ground protection mats resist rot, mold, and insect damage, making them ideal for repeated use in harsh conditions.

Marine decking, docks, and piers benefit from hdpe’s waterproof and slip-resistant properties.

Boat building and aquaculture infrastructure use hdpe sheet for its lightweight strength and chemical resistance.

Seawalls, marine buoys, and water sports equipment rely on hdpe for long-term protection and safety.

Outdoor furniture and playground equipment use hdpe ground protection mats for their low maintenance and weather resistance.

Construction sites choose hdpe ground protection mats for heavy-duty use, ensuring stable surfaces and equipment protection.

Hdpe ground protection mats offer environmental benefits as well. They are recyclable and do not leach harmful chemicals, supporting sustainable construction and marine projects.

You find marine plywood and other plywood grades essential in many construction and interior projects. Marine plywood provides reliable protection against moisture, making it suitable for boat building and exterior cladding. In structural construction, plywood supports flooring, roofing, and wall sheathing due to its strength and shock resistance.

Use marine plywood for boat hulls, exterior cladding, and areas exposed to moisture.

Choose plywood for interior paneling, cabinetry, custom furniture, and shelving.

Construction sites use plywood for concrete forming, soffits, and temporary structures.

Plywood’s flexibility allows for curved furniture, architectural features, and automotive interiors.

Fire-retardant and chemically resistant plywood variants offer protection in specialized environments.

Plywood’s high strength-to-weight ratio and impact resistance make it a cost-effective choice for many applications. You can select the right grade to match your project’s protection and durability needs.

You should match your material choice to your project’s environment and protection requirements. If you need ground protection in wet, salty, or high-traffic areas, hdpe ground protection mats provide superior performance and safety. For marine construction, playgrounds, and repeated use on construction sites, hdpe sheet ensures long-lasting protection with minimal upkeep.

If your project involves interior work, furniture, or structural components where rigidity and design flexibility matter, plywood or marine plywood may suit your needs. Always consider the level of exposure to moisture, chemicals, and physical stress. For heavy-duty use and maximum protection, hdpe ground protection mats stand out as the preferred solution.

Tip: Evaluate your project’s exposure to water, chemicals, and wear. Choose hdpe ground protection mats for outdoor, marine, or high-traffic environments. Select plywood for interior, decorative, or structural applications where traditional wood aesthetics and rigidity are important.

You have seen that HDPE sheets, like ABOSN’s Orange Peel Textured Surface Plastic Waterproof HDPE Slip Sheet, deliver unmatched durability, flexibility, and weather resistance. Plywood offers rigidity and traditional strength for indoor or structural projects. For outdoor, marine, or high-traffic environments, HDPE stands out as the superior choice. Always assess your project’s unique requirements before selecting a material.

Need more guidance? Contact ABOSN’s experts or review technical datasheets to make the best decision for your next project.

You benefit from HDPE’s resistance to water, chemicals, and UV rays. The material does not rot, swell, or degrade outdoors. Plywood absorbs moisture and can warp or rot, even with treatments.

You can use HDPE sheets for many demanding applications, but they do not provide the same rigidity as plywood. For load-bearing structures, plywood remains the better choice.

You clean HDPE sheets with soap and water. The surface resists stains, mold, and mildew. You do not need to seal, paint, or treat the material.

You can trust HDPE for marine and playground use. The material is non-toxic, slip-resistant, and does not leach harmful chemicals. It meets safety standards for outdoor and recreational environments.

You can expect HDPE sheets to last over 50 years with minimal maintenance. Plywood typically lasts 10–30 years, depending on exposure and upkeep.

You can recycle HDPE sheets easily. The material can be shredded, melted, and remolded into new products. This supports sustainable building practices.

You can choose from various thicknesses, colors, and surface textures. ABOSN offers custom sizes and finishes, including the orange peel textured surface for added slip resistance.

You should choose plywood for interior, decorative, or structural projects where rigidity and a traditional wood look matter most. HDPE works best for outdoor, marine, or high-traffic environments.