Views: 0 Author: Site Editor Publish Time: 2025-08-07 Origin: Site

Forecast Source | CAGR (%) | Forecast Period | Market Size Start | Market Size End |

|---|---|---|---|---|

MarketResearchFuture | 6.60 | 2025 - 2034 | $224.48 billion | $399.71 billion |

Verified Market Reports | 5.4 | 2026 - 2033 | $54.12 billion | $80.45 billion |

Fortune Business Insights | 4.58 | 2025 - 2032 | $18.90 billion | N/A |

Explore these seven facts about hdpe plastic to discover how it can elevate your packaging strategy.

HDPE plastic offers high strength and durability while remaining lightweight, making it ideal for packaging and construction.

HDPE sheets resist moisture, chemicals, and impacts, ensuring long-lasting protection for your products.

The material’s unique linear structure gives HDPE excellent rigidity and chemical resistance compared to other plastics.

HDPE sheets come in various thicknesses, sizes, and surface finishes, allowing customization to fit different project needs.

HDPE is widely recyclable and eco-friendly, supporting sustainability and reducing environmental waste.

Using HDPE sheets can lower long-term costs by reducing product replacements and shipping expenses.

HDPE meets strict safety standards for food contact and medical uses, ensuring non-toxicity and hygiene.

While HDPE performs well in many settings, it is not suitable for high-temperature or heavy load-bearing applications.

High density polyethylene, often called HDPE, stands out as one of the most reliable and versatile materials in modern packaging and construction. You encounter HDPE sheet plastic in everything from food containers to marine applications. When you choose a product like ABOSN’s 4x8 Feet Textured Marine Starboard HDPE Sheets, you benefit from a material engineered for strength, durability, and adaptability.

HDPE sheet offers a unique combination of physical and mechanical properties that make it a top choice for demanding environments. You will notice its high density, which ranges from 0.933 to 1.27 g/cm³. This density gives HDPE sheets their lightweight yet robust nature. The material resists impact, absorbs minimal moisture, and maintains stability even in wet or outdoor conditions.

Tip: HDPE sheets maintain their shape and strength even when exposed to water, chemicals, or sunlight, making them ideal for marine and outdoor uses.

The following table highlights the key physical and mechanical properties of HDPE sheet plastic:

Property | Range (Metric) | Description/Significance |

|---|---|---|

Density | 0.933 – 1.27 g/cm³ | Lightweight yet strong, ideal for packaging and construction. |

Tensile Yield Strength | 6.9 – 30 MPa | Withstands tension without deforming. |

Modulus of Elasticity | 0.483 – 1.45 GPa | Offers flexibility while maintaining strength. |

Flexural Yield Strength | 16.5 – 91 MPa | Resists bending forces, perfect for structural uses. |

Impact Strength (Izod, Notched) | 0.20 – 7.50 J/cm | Absorbs energy from impacts, reducing breakage. |

Melting Point | 26 – 135 °C | Handles a wide range of temperatures. |

Maximum Service Temperature | 80 – 120 °C | Performs well in both hot and cold environments. |

Water Absorption | 0.01 – 0.3 % | Stays durable in wet conditions. |

Coefficient of Friction | 0.20 – 0.28 | Provides a smooth surface, useful for sliding applications. |

You can rely on HDPE sheets for projects that demand strength, impact resistance, and thermal stability. These properties explain why HDPE sheet plastic is so popular in packaging, marine, and industrial settings.

The structure of HDPE sets it apart from other polyethylene types. You will find that HDPE consists of linear polymer chains with very few side branches. This arrangement allows the molecules to pack tightly together, resulting in high crystallinity and density. The tightly packed structure gives HDPE sheets their signature strength and rigidity.

Here’s a comparison of HDPE’s structure with other polyethylene types:

Property | HDPE Characteristics | Other Polyethylene Types Characteristics |

|---|---|---|

Chemical Structure | Linear polymer chains with very low or no long side branches | Branched polymer chains with various side branches |

Molecular Packing | Molecules pack tightly, resulting in high crystallinity and density | Loosely packed due to branching, resulting in lower density and crystallinity |

Density | Higher (approx. 0.933–1.27 g/cm³) | Lower (approx. 0.915–0.96 g/cm³) |

Mechanical Properties | High tensile strength, rigidity, chemical resistance | Generally lower tensile strength and rigidity |

Physical Appearance | Opaque | Often transparent (e.g., LDPE) |

Impact of Structure | Linear chains allow ordered, pseudo-crystalline structure | Branching causes irregular packing and less crystallinity |

This molecular structure explains why HDPE sheets outperform other materials in strength and durability. When you select ABOSN’s HDPE sheets, you gain the benefits of a material that resists breakage, absorbs impacts, and stands up to harsh environments. The structure also provides excellent chemical resistance, making HDPE sheet a smart choice for packaging and industrial applications.

You can trust HDPE plastic to deliver consistent performance, whether you need it for packaging, marine construction, or creative projects. The unique combination of properties and structure makes HDPE sheets a leading solution for a wide range of uses.

When you choose hdpe sheets for your projects, you unlock a range of benefits that set this material apart from other plastics. These benefits make hdpe a top choice for packaging, industrial, and outdoor applications. Let’s explore how hdpe sheets in action deliver outstanding performance in demanding environments.

You need materials that stand up to daily wear and tear. Hdpe sheets offer superior durability and impact resistance, which means your products stay protected during transport and handling. Unlike many other plastics, hdpe maintains its structural integrity even after repeated use. This durability comes from the material’s unique molecular structure, which allows it to absorb impacts and recover from deformation. Hdpe sheet also resists scratches and dents, making it ideal for reusable packaging and industrial storage.

Property / Polymer | HDPE | PET | PP (PP381, PP955) |

|---|---|---|---|

Elastic Recovery | Highest | Lowest | Slightly higher than PET |

Impact Resistance | Excellent | Good | Good |

Surface Wear | Moderate | Low | Intermediate |

You can rely on hdpe sheets to provide long-term performance, especially in environments where strength and flexibility matter most.

Hdpe sheets excel in environments where exposure to chemicals is common. You benefit from their ability to resist most acids, bases, and solvents. This chemical resistance makes hdpe a safe choice for food packaging, industrial tanks, and landfill liners. Hdpe does not require harmful additives to achieve this resistance, unlike some other plastics. However, you should note that strong oxidizing acids and certain organic solvents can affect hdpe over time. For most applications, though, hdpe sheets protect against moisture, bacteria, mold, and corrosion, preserving the quality of your products.

Note: Always assess the specific chemicals your project will encounter to ensure hdpe sheet is the right fit.

Outdoor applications demand materials that withstand sun, rain, and temperature changes. Hdpe sheets deliver excellent UV and weather resistance, especially when you select UV-stabilized or marine-grade options like those from ABOSN. These sheets retain their mechanical properties and appearance for years, even under harsh sunlight or extreme weather. Hdpe outperforms many other plastics, such as ABS and PVC, in outdoor durability. You can use hdpe sheets for marine construction, playgrounds, and outdoor cabinetry without worrying about fading, cracking, or frequent replacement.

Hdpe sheets resist UV degradation, maintaining color and strength.

They perform well in snow, rain, and fluctuating temperatures.

Marine-grade hdpe sheets from ABOSN offer added protection for water-based environments.

When you see hdpe sheets in action outdoors, you notice their ability to maintain performance and appearance over time. This reliability makes them a smart investment for any project exposed to the elements.

When you explore the many applications of hdpe sheets, you discover their unmatched versatility. You see hdpe sheets in action across industries, from packaging to construction to creative projects. Their unique properties—strength, chemical resistance, and weather durability—make them a preferred material for countless uses.

You rely on hdpe for a wide range of packaging solutions. The material’s strength and chemical resistance ensure that your products remain safe during storage and transport. Hdpe sheets serve as the foundation for containers, bottles, and industrial packaging. You benefit from their moisture resistance and ability to withstand rough handling.

Packaging Application | Description |

|---|---|

Plastic Containers & Bottles | Used for manufacturing containers and bottles for cleaning agents, cosmetics, and food items. |

Packaging Films and Bags | Processed into films and bags offering moisture resistance, tear resistance, and flexibility. |

Industrial Packaging | Used to create crates, pallets, and boxes providing durability and protection during transport. |

You also find hdpe sheets in food and beverage packaging, where hygiene and safety matter most. Many hdpe sheets are food safe, non-toxic, and easy to clean, making them ideal for cutting boards, storage bins, and conveyor systems.

Hdpe sheets play a vital role in industrial environments. You choose them for their high strength-to-density ratio, chemical resistance, and ease of fabrication. In construction, you use hdpe sheets for marine decking, cabinetry, and piping systems. The material replaces wood in outdoor furniture, decks, and docks, offering superior moisture and mildew resistance.

You use hdpe sheets in water management infrastructure, such as levees and containment structures.

You find them in automotive, agricultural, and medical device components.

Hdpe sheets are easily machined, welded, and thermoformed, supporting diverse manufacturing needs.

You benefit from their use in architectural facades, insulation boards, and greenhouses.

Hdpe sheets outperform traditional materials in marine and outdoor settings. You gain durability, low maintenance, and sustainability, especially when you select recycled or recyclable options.

You unlock new possibilities for recreation and creativity with hdpe sheets. The material’s moldability allows you to design playground equipment, outdoor furniture, and landscaping features. Hdpe resists mold, mildew, and insects, ensuring long-lasting performance in parks and leisure facilities.

You see hdpe sheets in playgrounds, benches, and safety barriers.

The non-slip surface and vibrant colors support safe, attractive recreational spaces.

Hdpe sheets require minimal maintenance, with no need for waterproofing or staining.

You use them in innovative projects like plastic boats, carnival games, and museum displays.

ABOSN’s customization options, including color core hdpe sheets, let you create signage and architectural elements that stand out. You tailor size, color, and surface finish to match your vision, making hdpe sheets a top choice for creative and functional projects.

Tip: Hdpe sheets support sustainable recreational spaces by using recycled materials and offering long service life.

You experience the full range of applications of hdpe sheets when you choose a material that adapts to your needs—whether for packaging, industry, or creative design.

When you select HDPE sheets for your project, you gain access to a world of flexibility and customization. You can tailor the material to fit your exact requirements, whether you need a specific thickness, size, or surface finish. This adaptability makes HDPE a top choice for industries that demand both function and style.

You can choose from a wide range of thicknesses and sizes when working with HDPE sheets. Most manufacturers offer sheets in thicknesses from as thin as 1 mm up to 30 mm, covering everything from lightweight packaging to heavy-duty industrial applications. Standard sheet sizes often include 4 feet by 8 feet, but you can also find options up to 5 feet by 10 feet or even larger. ABOSN provides sheets with a maximum width of 2500 mm and can produce any length you need, ensuring you get the right fit for your project.

Here is a quick overview of common thickness categories and their typical uses:

Thickness Category | Thickness Range (mm) | Typical Applications |

|---|---|---|

Thin Sheets | 0.3 - 2 | Packaging solutions |

Medium Thickness Sheets | 3 - 10 | Agricultural applications |

Thick Sheets | 10 - 30 | Industrial uses |

You can see that the types of hdpe sheets available cover a broad spectrum, making it easy to match the material to your specific needs. Whether you require a thin, flexible sheet for packaging or a thick, sturdy panel for construction, you have plenty of options.

You also have the ability to choose from several surface finishes, each designed to enhance performance in different environments. The most common finishes include plain, matte, embossed, and textured surfaces. Each finish offers unique benefits:

Surface Finish | Performance Characteristics and Applications |

|---|---|

Matte Sheets | Long lifespan; do not dull knives; resistant to bacteria; acid resistant; FDA and NSF approved; ideal for cutting boards. |

Smooth Sheets | Easier fabrication; superior chemical resistance; high tensile strength; moisture and impact resistant; ideal for tank linings. |

Antiskid Sheets | Designed for marine applications; provide slip and skid resistance for safety. |

Textured/Matte | Help hold food in place without slipping; preserve knife sharpness; beneficial in food preparation environments. |

You can select the surface that best matches your application. For example, a textured finish works well in food preparation areas, while a smooth finish is ideal for tank linings and industrial uses. The types of hdpe sheets you choose can also include anti-skid surfaces for marine or outdoor projects.

ABOSN stands out by offering full customization. You can request specific sizes, colors, and surface finishes to meet your project’s demands. This level of customization supports branding, safety, and performance goals across industries. As trends move toward more sustainable and innovative packaging, you benefit from HDPE’s adaptability and the ability to create solutions that fit your exact needs.

Tip: Customizing your HDPE sheets not only improves functionality but also helps your products stand out in the market.

You play a key role in protecting the environment when you choose HDPE sheets for your packaging and construction needs. HDPE stands out as one of the most eco-friendly and easily recyclable plastics available today. Most recycling centers accept HDPE, making it a preferred choice for businesses and consumers who want to reduce waste. As a BPA-free and non-toxic plastic, HDPE is safe for food and beverage storage, which adds to its sustainability profile.

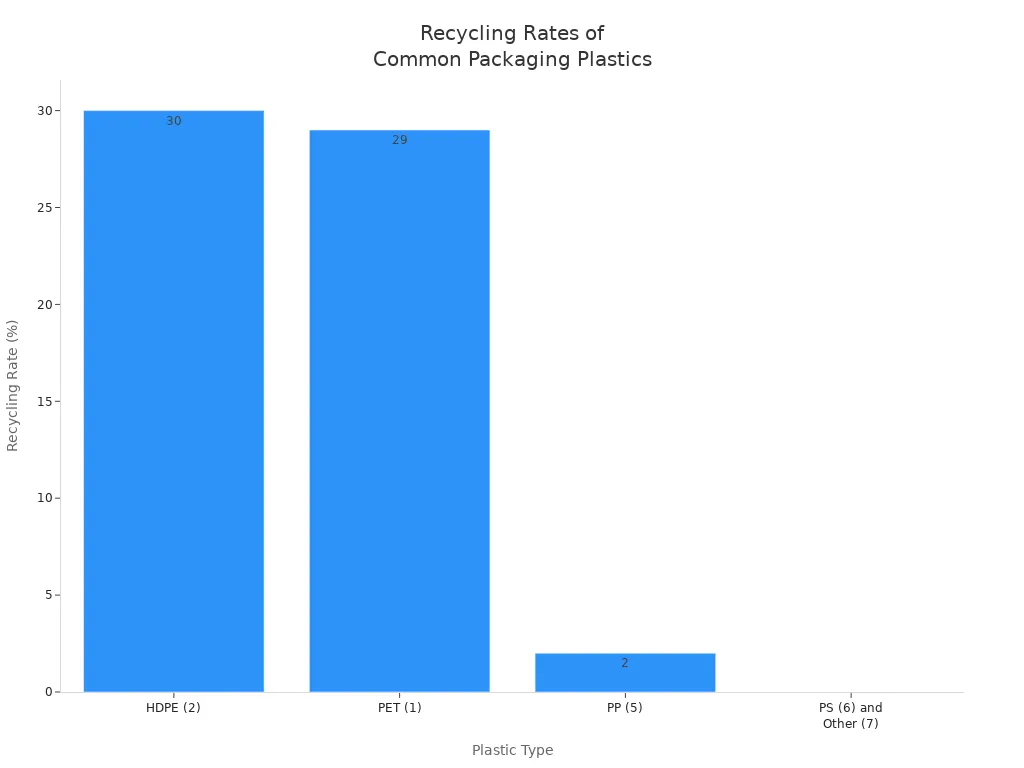

When you compare HDPE to other common packaging plastics, you see clear advantages. Unlike PVC, which is rarely recycled due to harmful additives, or PP, which faces technical and economic recycling challenges, HDPE offers a straightforward recycling process. You can recycle HDPE multiple times without losing its strength or durability. This makes it a truly recyclable material that supports a circular economy.

Plastic Type | Recyclability | Recycling Rate (US) | Recycling Challenges | Typical Downcycled Products |

|---|---|---|---|---|

HDPE (2) | Widely accepted at most recycling centers globally; one of the easiest plastics to recycle | ~30% for bottles | None significant; BPA-free and non-toxic | Plastic lumber, outdoor furniture, benches, curbs |

PET (1) | Widely recycled but requires different recycling process than HDPE | ~29% for bottles | Needs separation from HDPE; single-use plastic concerns | Shredded into pallets for reuse |

PVC (3) | Generally not recyclable in normal collections | N/A | Contains harmful additives; recycling not common | N/A |

PP (5) | Recyclable but low rates due to economic and technical challenges | 1-3% | Difficult and expensive; odor issues; recycled material often unsuitable for packaging | Plastic lumber, park benches, auto parts |

PS (6) and Other (7) | Not recycled | 0% | Not accepted in recycling streams | N/A |

You help close the loop by using and recycling HDPE products. This action reduces landfill waste and supports the creation of new, useful items like outdoor furniture and playground equipment.

You make a positive impact on the planet when you select HDPE sheets for your projects. HDPE’s sustainability comes from its durability, long lifespan, and ability to be recycled into new products. You reduce the need for new raw materials, which helps lower deforestation and the environmental costs of manufacturing. HDPE’s weather resistance and chemical stability mean you replace products less often, which cuts down on waste.

Consider these environmental benefits when you use HDPE:

You reduce the demand for virgin materials by choosing recycled HDPE.

You extend product life because HDPE resists moisture, chemicals, and harsh weather.

You support recycling programs, since HDPE is accepted by most curbside collections.

You help preserve natural ecosystems by using a recyclable material that does not require frequent replacement.

Non-recyclable plastics like PVC and polycarbonate often contain hazardous additives and do not break down in the environment. These materials increase pollution and harm ecosystems. In contrast, HDPE’s recyclability and reuse potential give you a responsible way to meet your packaging and construction needs without sacrificing performance or cost.

Tip: By choosing HDPE, you support a cleaner environment and set a standard for sustainable business practices.

You want packaging solutions that balance performance and cost. HDPE sheets deliver on both fronts. While the initial price of HDPE may be higher than some plastics like LDPE or PET, you gain significant savings over the product’s lifecycle. HDPE’s durability means you replace packaging less often, which lowers your long-term expenses. You also benefit from its resistance to weather, chemicals, and impact, reducing the risk of product loss or damage.

Consider this comparison of material costs and performance:

Material | Relative Cost Compared to HDPE | Notes on Cost and Performance |

|---|---|---|

HDPE (virgin) | Baseline (~$8.50/kg) | Low-cost, durable, recyclable |

Acrylic | 2-5 times more expensive | Higher price, certain benefits |

Polycarbonate | 2-5 times more expensive | Higher price, better impact resistance |

ABS | 2-5 times more expensive | Higher price, engineering plastic |

LDPE | Cheaper than HDPE | Lower initial cost, less durable |

PET (virgin) | $0.80–$3.00/kg (lower) | Lower virgin cost but varies widely |

Recycled HDPE | ~$2.50/kg (cheaper than virgin) | Cost-effective recycled option |

Recycled PET | $0.80–$1.20/kg | Lower recycled cost, performance varies |

You see that HDPE offers a strong balance between cost and performance. Although LDPE and PET may cost less upfront, HDPE’s strength and longevity mean you spend less on replacements and repairs. When you compare HDPE to glass or metal, the savings become even clearer. Glass packaging produces 75% higher emissions, and aluminum has a 96% higher environmental impact than HDPE. You also avoid the extra weight and shipping costs that come with traditional materials.

Tip: Choosing lightweight HDPE sheets from ABOSN helps you cut shipping costs and reduce your carbon footprint.

You improve your production process when you use HDPE sheets. The lightweight nature of HDPE makes handling and transportation easier, which speeds up operations and lowers labor costs. You can customize HDPE sheets in thickness, size, and color, which streamlines your packaging process and reduces waste.

Here are some ways HDPE boosts manufacturing efficiency:

You use less energy during production thanks to modern process engineering.

You experience fewer product failures because HDPE resists chemicals and impact.

You protect your goods with HDPE’s excellent barrier properties against moisture and dust.

You recycle HDPE easily, which reduces your need for new raw materials.

The manufacturing process for HDPE sheets is straightforward. You start with resin pellets, melt and shape them, then cool and trim the sheets to your specifications. This efficient process ensures you receive high-quality, consistent products every time.

When you choose ABOSN’s HDPE sheets, you gain a cost-effective solution that supports both your budget and your operational goals. You get reliable performance, lower lifecycle costs, and a smoother manufacturing experience.

You must prioritize safety when selecting HDPE sheets for packaging, especially in food and medical applications. HDPE stands out as a non-toxic material that does not release harmful substances or alter the taste and smell of products. To ensure safety, HDPE must meet strict standards:

HDPE must comply with U.S. FDA regulation 21 CFR 177.1520, which governs polyethylene resins in contact with food. This regulation ensures that no harmful substances migrate into food.

The material is recognized as safe for food contact, making it suitable for containers, cutting boards, and medical packaging.

European Union regulations also apply to plastics intended for food contact, providing an extra layer of safety for international markets.

Certifications such as ISO 22000 support food quality and safety management during production.

HDPE’s chemical resistance, low permeability, and temperature tolerance further enhance its suitability for sensitive packaging needs.

Tip: Always verify that your HDPE sheets carry the necessary certifications for your intended application.

You face a dynamic regulatory landscape when using HDPE packaging. Governments worldwide enforce strict policies to reduce plastic waste and promote recycling. You must ensure your packaging meets these evolving requirements:

HDPE packaging must comply with regulations on single-use plastics and mandated recycling rates.

Brands often invest in technologies and source recycled materials to meet compliance standards.

In the United States, FDA and EPA regulations require food-safe, BPA-free, and recyclable HDPE packaging.

Pharmaceutical packaging must meet rigorous safety, tamper-evident, and contamination prevention standards, enforced by agencies like the FDA, EMA, and WHO.

North America and Europe promote recyclable HDPE packaging, focusing on reducing carbon footprints and plastic waste.

There is a growing shift toward bio-based, reusable, and carbon-neutral HDPE solutions.

You should work closely with suppliers who provide documentation and certifications. This approach helps you maintain compliance and build trust with your customers.

While HDPE sheets offer many advantages, you need to consider their limitations in certain environments. The table below summarizes key factors:

Limitation Category | Description |

|---|---|

Thermal Performance | HDPE melts at 120-130°C. It is unsuitable for sustained high temperatures and may lose strength. |

Mechanical Strength | Lower tensile strength compared to some engineering plastics. Not ideal for heavy load-bearing uses. |

Environmental Impact | HDPE comes from petrochemicals. Production and disposal contribute to greenhouse gas emissions. |

You may encounter customer questions about stress cracking, UV resistance, and flammability. HDPE performs well in most packaging and construction settings, but you should avoid using it in applications that require high-temperature resistance or heavy structural support.

Note: Always match the grade and specifications of HDPE to your project’s demands for optimal performance and safety.

You now understand the seven essential facts about HDPE plastic that shape smart packaging choices:

High strength-to-density ratio

Excellent resistance to moisture, chemicals, and impact

Rigid and durable for diverse applications

Strong barrier properties

Lightweight for lower transport costs

Widely recyclable for sustainability

Some design limitations

Choosing ABOSN’s high-quality HDPE sheets ensures superior performance and longevity.

Consult with material experts to select the right HDPE solution for your next project.

HDPE stands for High-Density Polyethylene. You use this thermoplastic polymer in packaging, construction, and many industrial applications because of its strength, durability, and chemical resistance.

Yes, you can use HDPE sheets for food contact. HDPE meets FDA and EU food safety standards. You often see it in cutting boards, food containers, and packaging that require hygiene and non-toxicity.

You clean HDPE sheets with mild soap and water. Avoid harsh chemicals or abrasive pads. HDPE resists stains and bacteria, so you can keep surfaces sanitary with regular cleaning.

Yes, you can use HDPE sheets outdoors. UV-stabilized and marine-grade HDPE resists sunlight, rain, and temperature changes. You often see it in marine construction, playgrounds, and outdoor furniture.

You can recycle HDPE sheets at most recycling centers. HDPE is one of the most widely recycled plastics. You help reduce waste and support sustainability when you recycle HDPE products.

You can customize ABOSN HDPE sheets by thickness, size, color, and surface finish. ABOSN offers options like matte, embossed, and textured surfaces to match your project’s needs.

You find HDPE sheets in packaging, marine, construction, agriculture, recreation, and signage industries. Their strength, chemical resistance, and weather durability make them a top choice for many professionals.